Preface:

Talc also known as Hydrated Magnesium Silicate or Soapstone. Talc is the softest known mineral which is chemically inert, organophilic & water repellent.

The characteristic depends on its geology based on its location. Although talc is lamellar, its platelet size differs from deposit to deposit. Small crystals provide a compact, dense ore, known as micro lamellar talc.

Generally, talc is found in white color but at times it could also be grey, green, blue, pink, cream & even black.

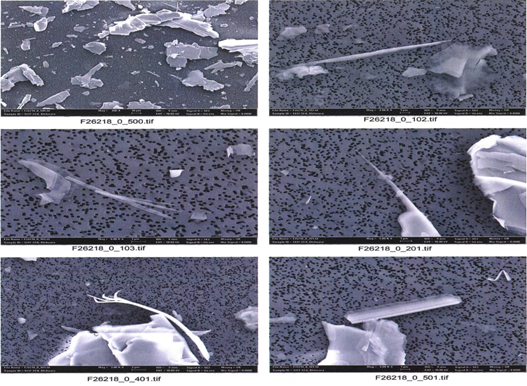

Talc Under Microscope

Paint:

An ideal multi-functional pigment, filler & extender in water borne, solvent borne & powder-coat based architectural & industrial paints, where they improve mechanical properties, optical properties & production process.

Benefits of Talc:

- Provides corrosion resistance;

- TiO2 extender;

- High specific surface area;

- Good matting properties;

- Excellent flatting agents;

- Good viscosity;

- Easy dispersion;

- Rheological properties to gel.

Plastics:

Talc is an excellent reinforcing filler in polypropylene & engineering thermoplastics for automotive parts, domestic appliances, E&E components & food packaging. Talc is an ideal anti-blocking solution for LDPE & LLDPE films.

Our highly lamellar talc’s make ideal reinforcing filler in PP & TPO for application which requires greater stiffness & better dimensional control over a range of temperatures.

High lamellar Talc increases part stiffness, improves impact resistance providing excellent impact balance. It also improve heat resistance- essential for automotive under-the-hood parts or for microwave resistance thermoformed plastics.

This grade of talc can be used in Automotive Compounds, Non- Woven Color Master-batch, Anti Fabulation Master-batch, Food Packaging & Films, PVC Cables, Film & Pipe Application, Wood Plastic Composites.

Cosmetics:

Talc has been used as body powder is an ideal carrier for perfumes. Our talc provides the silkiness in blushers & eye shadows, the transparency and the sheen of the powder compacts.

Talc is chemically inert, hydrophobic & organophilic. Our talc enhances the final properties of body powders, make-ups, soaps & sydents. Our talc have high purity, softness & silkiness with excellent whiteness and brightness. It acts as fragrance carrier, inert carrier, oil-base replacement, optical properties, and pigment extender.

Ceramic:

Our talc is used in Frits, Glazes & engobes. Our talc gives good melting behavior & improves thermal expansion & fusion. It further enhance the whiteness while improving acidic resistance. Our talc is also known to increase glaze body, reinforcing crazing resistance, reducing pinholes and most important it reduces formulation cost.

Talc has many functional properties like:-

- Fluxing agent used in combination with feldspar;

- Lowers Fusion Temperature;

- Speeds up the vitrification process;

- Improves composition viscosity;

- Increases surface tension;

- Stabilizes thermal expansion – important in large format tile;

- Savings in terms of energy & CO2 emission;

- Controls moisture expansion in tile body;

- Improves MOR (Modulus of Rupture); &

- Improves Dimensional Stability.

Paper

Talc works as very good agent for control of pitch & stickiness throughout paper making process as it attracts them onto its platelets making them harmless and preventing them from agglomerating. These natural properties enhances the printability of the finished paper. Used as filler, its blush improves whiteness.

The right level of gloss, matt or silk finish can be achieved by simply fine tuning talc particle size.

Talc also improves run ability, reducing machine downtime, cleaning times, prolonging felt lifetimes and boosting productivity.